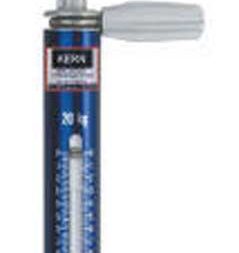

Leeb Hardness Tester HMP.

€1,290.00 ex. VAT

HMP. Leeb Hardness Tester Max 960, Min 170, d= 1 HB,HL,HRB,HRC,HV,MPa

Pure quality for professional users

ISO Calibration Certificate

Add the following item to your cart when purchasing your Kern product in order to add ISO Calibration Certificate to your product. Click product link for more information

| SKU: | HMP. |

|---|---|

| Workplaces: | Measuring Equipment |

| Categories: | Hardness testing of metals, MEASURING EQUIPMENT, Measuring instruments |

| Tags: | Kern |

| Brand: | Kern |

Leeb Hardness Tester HMP.

Certificates Available:

ISO Calibration Certificate

Add the following item to your cart when purchasing your Kern product in order to add ISO Calibration Certificate to your product. Click product link for more information

ISO Calibration Certificate 961-131

Product Description:

Automatic recognition of the impact (rebound) sensor connected to the HMP.

Measures all metal samples (> 5 kg, thickness > 8 mm)

Mobility: In comparison with stationary table-top devices and testing devices with an internal sensor, using the SAUTER HMP. offers the highest level of mobility and flexibility

External impact sensor standard (Type D)

All measurement directions possible (360°) thanks to an automatic compensation function

Software and PC connection cable standard

Standard block for calibration with defnied HLD value standard

Support rings for bended testing samples available on request,

on request

Delivered in a hard carrying case

Internal memory for up to 100 data groups, with up to 32 values per group forming the average value of the group

Mini statistics function: displays the measured result, the average value, the impact direction, date and time

Measurement value display: Rockwell (B & C), Vickers (HV), Brinell (HB), Shore (HSD), Leeb (HL), tensile strength (MPa)

Automatic unit conversion: The measuring result is automatically converted into all specified hardness units

Precision: ± 1 % at 800 HLD

Measuring range tensile strength: 3742652 MPa (steel)

Minimum sample radius (concave/convex): 50 mm (with support ring: 10 mm)

Min. sample weight on a solid and stable support:

Sensor C: 1,5 kg

Sensor D, DC, D+15, DL: 5 kg

Sensor G: 15 kg

Minimum sample thickness:

Sensor C: 1 mm

Sensor D, DC, D+15, DL: 8 mm

Sensor G: 10 mm

- Weighing range Max:

- Readout d:

- Max. Length:

- Read Out Length:

- Max. Hardness Leeb: 960

- Min. Hardness Leeb: 170

- Read Out Hardness Leeb: 1

- Max. Force:

- Read Out Force:

- Verification value:

- Verification class:

- Minimum load:

- Reproducibility-Linearity:

- Verification:

- Price Verification:

- DKD Certificate:

- Price DKD certificate:

- ISO calibration certificate: 961-131

- Price ISO calibration certificate: 120

- Dimensions housing WxDxH:

- Material weighing plate:

- Dimensions weighing plate WxDxH:

- Weighing area WxD:

- Weighing space WxDxH:

- Display digit height:

- Weighing units: HB HL HRB HRC HV MPa

- Stabilisation time:

- Weighing system:

- Rechargeable battery:

- Charging time:

- Operating time Backlight on:

- Input voltage:

- Power Supply For Country:

- Power Supply Kind:

- Battery UN Number:

- Operating time: 100 h

- Reference quantity:

- Environment max. humidity:

- Environment max. temperature: 50 °C

- Environment min. temperature: 0 °C

Available Accessories

961-131,AHMR DC,AHMR DL,AHMR C,AHMR D+15,AHMR G,MPS-A09

Related

products

-

Spring Scale 285-102

€215.00 ex. VAT -

Spring Scale 285-352

€215.00 ex. VAT -

Spring Scale 281-101

€108.90 ex. VAT -

Pressure-Set For Spring Balances 285-890

€93.90 ex. VAT -

Spring Scale 285-052

€200.00 ex. VAT -

Spring Scale 285-502

€255.00 ex. VAT -

Spring Scale 281-151

€103.90 ex. VAT -

Spring Scale 285-202

€205.00 ex. VAT -

Spring Scale 281-201

€103.90 ex. VAT -

Spring Scale 287-102

€93.90 ex. VAT -

Adaption Set For Spring Balances 285-893

€55.00 ex. VAT -

Spring Scale 287-100

€93.90 ex. VAT -

Spring Scale 281-451

€113.90 ex. VAT -

Spring Scale 287-106

€93.90 ex. VAT -

Spring Scale 281-752

€115.00 ex. VAT -

Spring Scale 287-104

€93.90 ex. VAT -

Spring Scale 281-401

€113.90 ex. VAT -

Spring Scale 281-301

€103.90 ex. VAT

Sending...